Why are the Day Six Centric System components the best?

Why are the Day Six Centric System components the best?

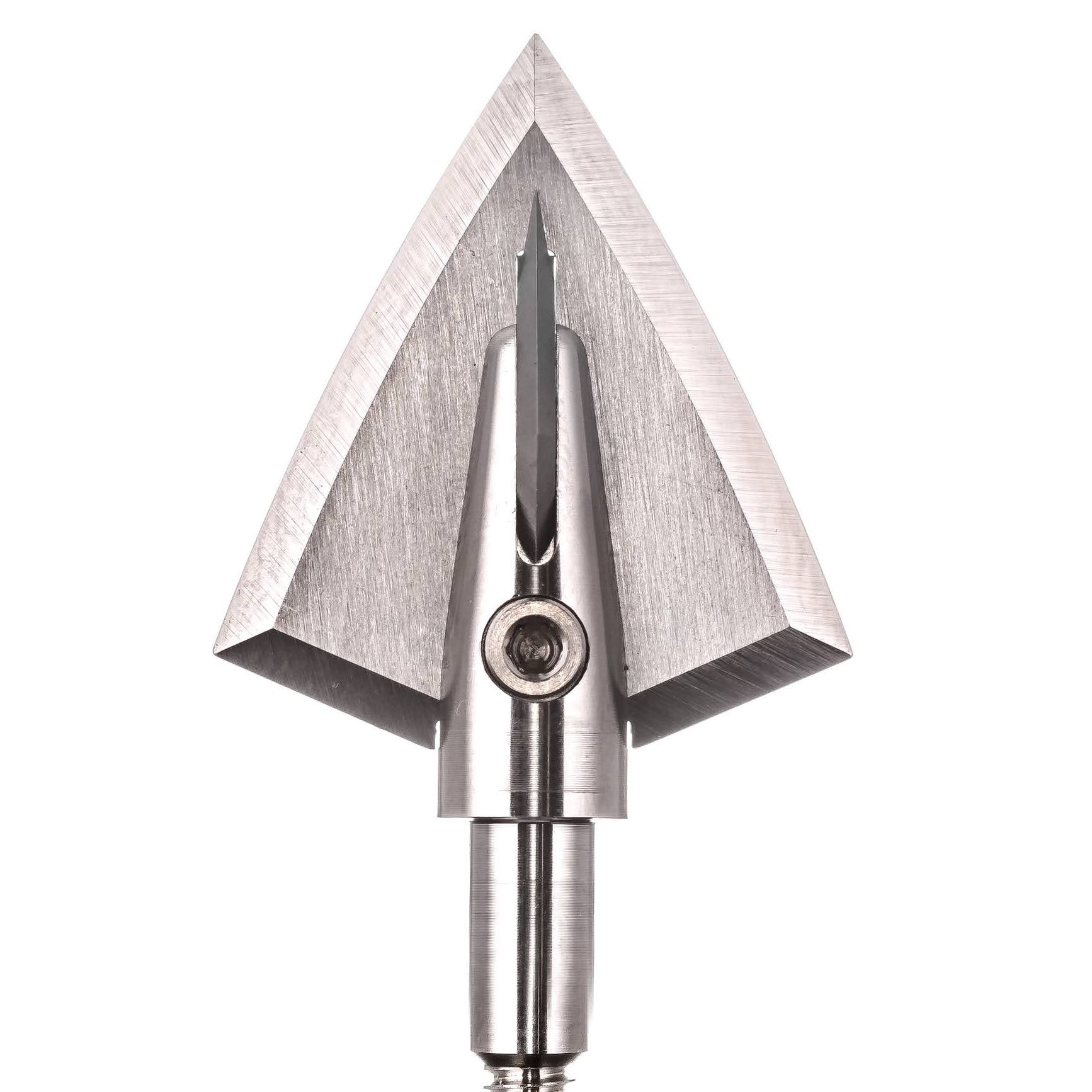

The Achilles heel of the micro diameter arrow has always been the components.

Either they don’t spin true, they hang up in bag targets, or they simply come off in the target, leaving the shooter with a useless arrow. While the advantages of the micro diameter arrow far outweigh that of larger diameter shafts (for another discussion), the clunky components offered with them have historically been a deterrent.

So what makes our Centric System any different? Well, there’s quite a few advantages to the design that address the common problems normally associated with micro diameter components. Let’s start with achieving the best concentricity (spinning true). The part of a shaft that’s perfectly straight is the inside, so in order to achieve the best concentricity, you need to index the component there instead of the outside. To paint a mental picture, imagine an arrow shaft like a roll of paper towels. The cardboard tube on the inside is perfect, but after many layers of paper towels, the outside isn’t perfectly round. Our components rely on the inside of the shaft for alignment and by having the collar mechanically attached via threads it can “float” around the outside of the shaft and not be pushed to one side. By machining our collars to be just .002” larger than the outside diameter of our shafts, once the .001” gap is filled with epoxy it becomes a monolithic unit with the shaft and spins perfectly true and is extremely tough.

Another common issue solved by having the collar and insert mechanically attached via threads, is the tendency for components to come off in a target. The threads provide a mechanical bond, and the epoxy provides a chemical bond. Additionally, by having both components epoxied to the shaft both inside and out, you’re effectively doubling the surface area for the epoxy to bond.

Hate getting the components stuck trying to remove an arrow from a bag target? So do we! Having each component machined to such a tight tolerance with each size 2 shaft allows us to taper the trailing end of the collar down to .010” thickness, hence reducing the edge that tends to stick in a bag target making it a breeze to remove. This also reduces the amount of rearward force on the component when pulling the arrow out of a target and helps eliminate components coming off.

In summary, the Centric System components are great on their own, but when married precisely to our thick wall shafts, the result is a solid, bombproof front of the arrow that maintains its structural integrity as well as concentricity. All Day Six arrows come standard with our patented Centric System components.

We have included a link to our video tutorial on installing the Centric compo-

nents. It’s super easy, and our design makes it achievable by even the most novice arrow builder.

As always, thank you for all your support! We are truly blessed with the best cus-tomers and we love coming to work every day because of you.

-Bryan Broderick, Day Six Gear