The Best Just Got Better

The Best Just Got Better

In June of 2019, I designed a glue-in or screw-in style broadhead system that had an extended shank with the goal of achieving maximum durability and concentricity when used with micro (4mm) diameter shafts. Once prototyped, simple testing would reveal that while it did improve concentricity it was actually less durable.

Simply put, any arrow component, head, point, etc is only as strong as its weakest part. What was discovered to be the weakest point on this style system was the shoulder, or shank of the head, where it enters the shaft. By reducing this section to .165” from the standard .204” diameter to allow total immersion into the micro diameter shaft it created a noticeable weak point (see below) and the head/point would snap off on the slightest of angled impacts. So I scrapped it.

When we are designing anything here at Day Six, we are always conscious of “the weakest unsupported point”. What does that mean you ask? Well, when a weak point is discovered we try and develop a way to “bridge” or “support” it with another component or material creating an overlap. Even with the addition of a collar, it still leaves the weak point exposed and unsupported so we had to come up with another solution.

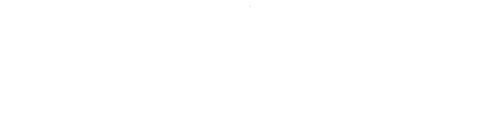

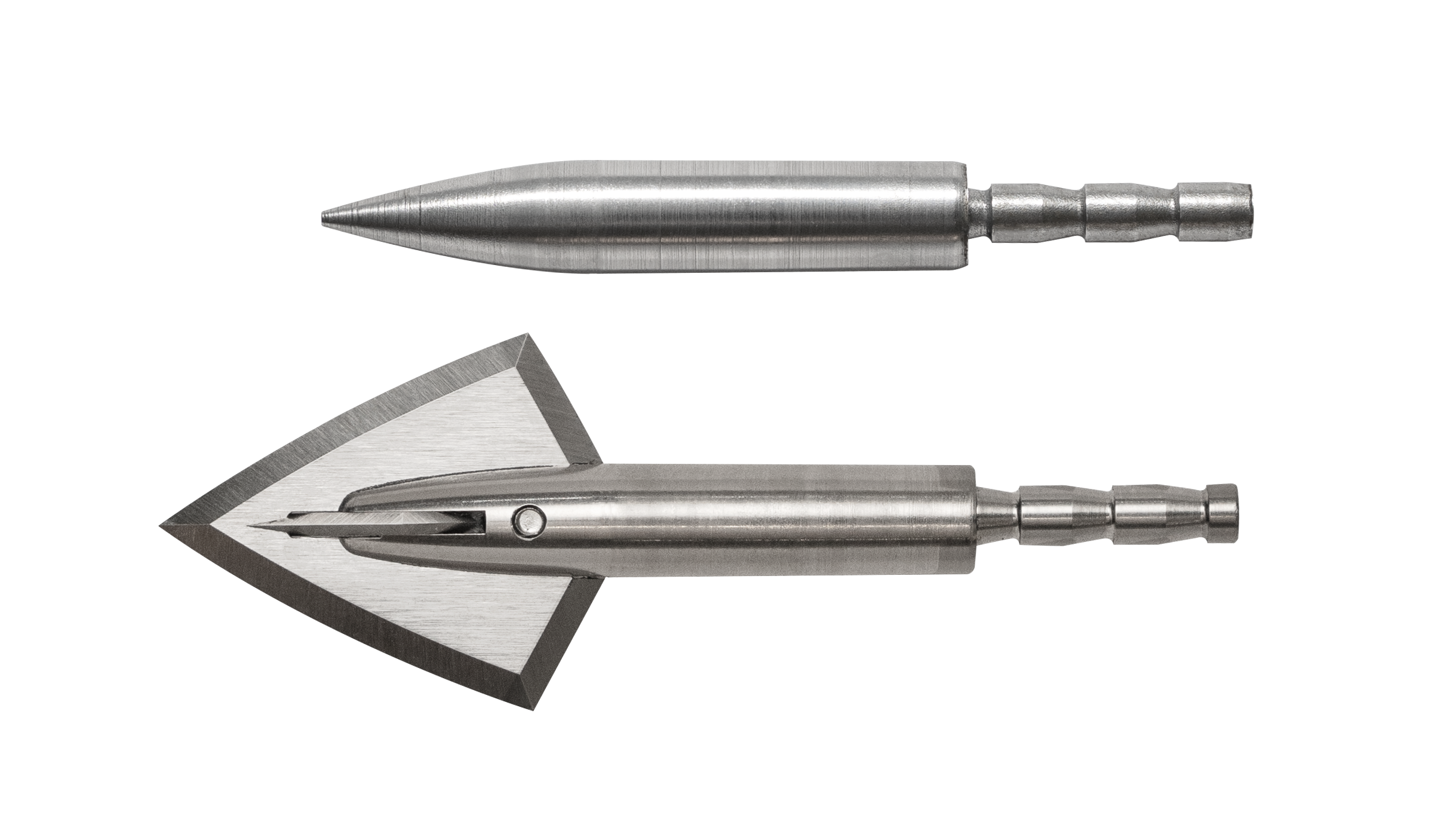

Our solution, the new EVO CS (Centric Series).

Available in three weights, the EVO CS (Centric Series) will be offered for our 4mm shafts. Featuring an integrated collar, this is essentially a “one-piece” monolithic unit that will provide the ultimate in durability as well as concentricity.

With matching weight field points, they can be installed using hot melt glue for easy exchange and broadhead alignment.

4mm total weights.

150, 175, 200.

While these are designed to fit perfectly with Day Six shafts, they will fit shafts from all other manufacturers as well. The OD of other manufacturers shafts will have to be cross referenced to determine the proper size.

The EVO Centric System will be available for immediate shipping February 1st and as with all Day Six broadheads they are 100% American made right here in WYOMING.

As always, thank you for your continued support of this small family run company.